This is currently the smallest Garrett turbocharger to date. This small frame turbocharger GT0632SZ recently came out and have only been available now since late 2012.

Being so small and tiny it still have the capability to produce peak horsepower 80 hp at around 300.000 rpm and is best suited for engines between 100cc to 500cc. It's a popular choice now even for mopeds, perfect for go-karts, ATV's, scooters because the GT06 will work well down to 25hp also.

We can see from these pictures just how tiny the GT06 Turbocharger really is in comparison to a ordinary Coca Cola Can.

And also a picture showing how small the turbocharger compressor wheel is (32mm) with the compressor housing lifted off. Looking at the coins and the turbo compressor wheel you really start to see just how tiny this new Garrett Turbocharger is.

GT0632SZ Turbocharger Specifications

Model: 789997-1

CHRA: 800039-1

Bearing: Journal

Cooling: Oil

Compressor

Inducer: 22.63 mm

Exducer: 32 mm

Trim: 50

A/R 0.32

Turbine

Wheel: 30 mm

Trim: 72

A/R: 0.18

Wastegated

A reader have added the following:The inertia of the GT06 turbo rotor is 2.39e-06

The compressor map have also a very broad range and boost pressures can go up to 1.7 bar before this small turbocharger goes out of it's preferred work area.

Together with a good flowing engine there should not be any problem to get peak power at around 1 bar of boost pressure with this turbocharger.

Because the GT06 is so new not to many people have started using this turbocharger yet. Also due to reasons unknown there are also a lack of flanges for this turbo. Garrett have not updated it's catalog to include this turbocharger yet as of (March 5, 2013)

It's not a standard T25 and the only bolt pattern I see similar to this is that of the older GT12 small turbo turbine outlet shown here. Until more people start using this turbocharger to turbo all kinds of mopeds, scooters, atv, lawn mowers... We will not know for sure.

The good thing is that the turbine wheel is cast from "Inconel" material for extreme applications, it's oil cooled and it comes complete with a wastegate included.

Being so small and tiny it still have the capability to produce peak horsepower 80 hp at around 300.000 rpm and is best suited for engines between 100cc to 500cc. It's a popular choice now even for mopeds, perfect for go-karts, ATV's, scooters because the GT06 will work well down to 25hp also.

|

| Tiny Garrett GT06 Turbocharger VS Coca Cola Can |

And also a picture showing how small the turbocharger compressor wheel is (32mm) with the compressor housing lifted off. Looking at the coins and the turbo compressor wheel you really start to see just how tiny this new Garrett Turbocharger is.

GT0632SZ Turbocharger Specifications

Model: 789997-1

CHRA: 800039-1

Bearing: Journal

Cooling: Oil

|

| Tiny Garrett GT06 Turbocharger Compressor Wheel vs Coins |

Inducer: 22.63 mm

Exducer: 32 mm

Trim: 50

A/R 0.32

Turbine

Wheel: 30 mm

Trim: 72

A/R: 0.18

Wastegated

A reader have added the following:The inertia of the GT06 turbo rotor is 2.39e-06

The compressor map have also a very broad range and boost pressures can go up to 1.7 bar before this small turbocharger goes out of it's preferred work area.

|

| Garrett GT06 Turbocharger Exhaust View |

|

| Garrett GT06 Turbocharger Compressor Side View |

|

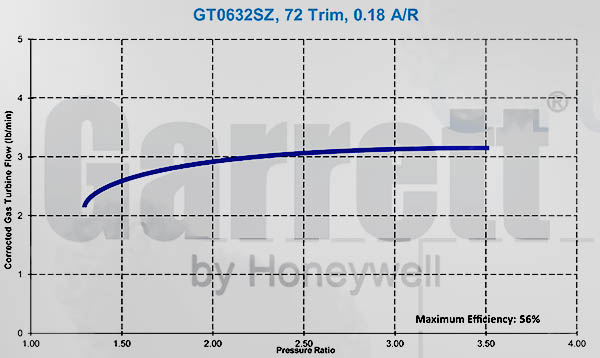

| GT0632SZ Turbine Flow 72 Trim 0.18 A/R |

|

| GT0632SZ Compressor Map Flow 50 Trim 0.32 A/R 32MM |

|

| Garrett GT06 Turbocharger GT0632SZ Measurements in MM Turbo Flanges Diameter Honeywell 1280x1474 |

Because the GT06 is so new not to many people have started using this turbocharger yet. Also due to reasons unknown there are also a lack of flanges for this turbo. Garrett have not updated it's catalog to include this turbocharger yet as of (March 5, 2013)

|

| Garrett GT1241 Specifications Flanges GT0632Z |

The good thing is that the turbine wheel is cast from "Inconel" material for extreme applications, it's oil cooled and it comes complete with a wastegate included.

I also have more technical pages for you that will come in handy. They will be of great help when looking at compressor maps Use the conversion tools And you will be able to calculate airflow, pressure and HP figures for the turbocharger you are interested in.

174 comments:

Do you have information about the inertia of the turbine and compressor wheels (Gt06) ?

Sorry no additional information about the turbo compressor wheel or turbine wheel as of this moment. Mostly because the small Garrett GT06 turbocharger is new to the turbocharger scene. I will update with more information as soon as I get any. Thanks.

Thanks man, would be really cool because i need this inertia value for detailed turbocharger simulation! Greetings

Dear all, any idea to use tiny turbocharger at small diesel engine, Kubota RD65, 376CC, 5.5HP at 2200 Rpm. i will use this small diesel engine for DC Diesel Generator with Variable Engine Speed. 1200 to 2200 Rpm. Thank You

I'm building a motorized bike with a Lifan 125cc 4-stroke engine and was wondering if I could use it on that engine?

Hello, yes the 1 cylinder Lifan 125cc 4-stroke engines and similar sized bike engines like Honda, will spool up the Garrett GT06 Turbocharger. The higher you are able to rev the engine the better (+8000rpm). But to get the most of this small Garrett GT06 turbocharger on small engines you need to be able to tune the ignition timing as well as the fuel and have the right size and length (really short) turbo manifold to keep the exhaust gases spinning the turbo.

Small Diesel engines will have a hard time spooling the turbocharger if the rpm is so low (2000rpm). Also Diesel engines have cooler exhaust gases because Diesels are more efficient, and that hurts the ability to get the turbocharger to spool up and you won't get much performace from a really small low rpm turbocharged diesel engine.

Can dis turbocharger be used for a single clyinder 400cc petrol engine??????

Hello, the Garrett GT0632Z turbocharger is small enough to be used on engines between 100cc to 500cc. If you have a really low power / low reving single cylinder engine (below 10hp) then you might have problems with it not spooling up good and building boost. But if this is a bike or ATV engine that makes some decent power, then you should not have any problems.

The inertia of the GT06 rotor is 2.39e-06

hey can i put this turbo on my stock 20hp briggs&stratton vanguard twin cylinder 570cc? would it hurt the engine to run it with stock pistons, connecting rods, and everything? basically can i put this small enough turbo charger on my lawnmower engine just the way it is, or would my engine only last 5 months before xploding or something please reply?

Hello Levi, yes you would be able to run the GT06 turbocharger on your 570cc Briggs & Stratton Vanguard V-Twin. I would advice you to try and get the engine to rev a bit more than the max 3.300rpm to further help spool the GT06 turbo. And also if you don't have already, you would need to modify the carburetor so it would still work and supply the extra fuel needed with a turbo fitted. This is normally done by adding boost pressure from the turbo to the float bowl. And you also need to get oil pressure to the turbocharger from the engine with an oil line and also an oil return made. As far as the twin 570cc Vanguard engine is concerned, the stated Compression Ratio of 8.2:1 means you should not have any problems if you keep an eye on the boost pressure and not go much above 10 psi. That should give you around 30-35hp. You can go higher. But if so, you need to look at fitting either an intercooler or running methanol / water injection to keep the engine from detonating, Because the engine is a V-twin it really helps. But you need to make sure you take care of the engine and have good oil and the right fuel mixture, then it should last without problems. If something does break, it usually is either the connecting rods or the bearings that will fail first in these types of engines.

Hope this helps and good luck.

ok, thank you so much for the information,,,yes i know the the oil lubercation and every thing, i actually have a li'l oil pressure gage hooked up to the oil filter base were the little senser is and when i start it up cold start in 30 degree F temperature, with the throttle all the way low, it still reads past 100 psi then it will change normal once it warms up, i have 5w-30 in it... thank you so much for the help,,,, i do have a few more questions though, on the top of the carburetor on my engine, theres to little screws right next to each other with a little pipe sticking out below each screw, those are the fuel mixture adjustments but I'm not sure what way to turn them,,, its winter time over here, when i turn them should i turn them to were the rpms will go a lil higher and it will run smoother, or adjust it back to where the idle goes down a little bit and it runs a bit rougher,,, I'm so sorry for all these questions man,,, my engine model is 351777 if that helps.

maby is there like a way i could take a picture of the carb and show you or email it to you? because you can see the whole thing in the pic,?

never mind i found my model carb and everything thanks man.

Would this be the ideal turbo for my 2014 Ninja EX300? Whats the ideal RPM range?

Hello Charles, at the moment the Garret GT0632SZ turbocharger would be your best choice for your 300cc Kawasaki Ninja. With the right exhaust and setup it should pretty much give you power from 8000 rpm all the way to the redline. And around 50 hp if you run E85 fuel and 1 bar (14 psi) boost on this engine. If you can't run E85 fuel you need to drop the compression ratio and try fitting an intercooler to be able to turn up the boost without the risk of detonation.

Very impressed with this little turbo, I have made a custom CNC billet A/R turbine housing for it.

http://www.post100.com.au/?page_id=105

Hello Dave is it?

That is some impressive work you have done on the Postie bike and some nice machining on that custom turbine housing and fabrication work on the bike too. Congrats on 180 km/h with that Postie Bike Salt Lake Racer, I topped out my Honda Z50 at 80km/h turning around 12-13000rpm still on the stock 49cc ages ago. So it's nice to see people still pushing these types of engines to the limit. World’s Fastest Indian movie is one of my favorites, I wish you best of luck to brake that 125mph record!

hola este turbo le servira a una Bera 200 es de 13 hp

Hello Jose, I don't know much about the Bera 200 but from what I can tell the Garrett GT06 will work on the Bera 200cc. It will start to make good power if you can rev it past 7-8000 rpm.

What would br the case if I mounted this to a 1200 cc vtwin Harley motor.

Quick spool of would the capacity of the engine be restricted as the small porting of the turbo ow would it be on gate to much. Mabye a gt12 would be a better choice. Only drama is block is air cooler so no coolant available

Just looking at basicly near instant spool and most way thru out the ref range ( limiter set at 7500) not looking at high boost mabye 5 to 10 psi as stock block

Best regards

Brian

Hi Brian, I say this small GT06 would definitely choke that 1200cc engine. Your Carburetor inlet is probably around 40mm stock and this GT06 turbo inducer is half that only 22.63mm.

It would spool up quick, but even the exhaust side would start to choke the top end power. And with only air cooling avaliable this turbo would also run hot just by being so small.

Like you said the GT12 would be a much better choice and even the GT15 would not be a bad pick either, might be a bit slower to spool but it would run cooler and you can keep the boost pressure down and still make the power.

Hi JD, I'm about to order this turbocharger to be installed in a small one-cylinder, 650cc, diesel engine. The current engine power is 14 hp @3600rpm. Do you think this Turbo will work with this small engine at this rpm range?

Besides that, I would like to know if I could use the same oil system as the engine or if I need to plug a separate oil pump? In any case, what is the oil pressure I should be looking for? can you recommend an appropriate oil pump?

Thanks a lot for your help,

Alvaro M.

Hi Guys! I'm currently trying to push my 799cc diesel smart fortwo past 80HP and mold like to know what you guys think. Should i go with this GT06 or GT12?

Hi Alvaro, the GT06 turbocharger is probably your best option for a 650cc engine. But because it's a Diesel to help it spool up better I would recommend that you try and keep the exhaust going to the turbocharger as short as possible and also without bends. And also try and use a similar small size pipe diameter going to the turbo. This would help the turbocharger build boost faster on your Diesel engine.

You don't need a separate oil pump, this is a journal bearing turbocharger so you can run an oil line from your engine. Your oil line hose and fittings will act as an oil pressure restrictor in this case.

It's only the ball bearing turbochargers that you don't want to run too high oil pressure into because ball bearings don't need as much oil.

Hi, for a 799cc Diesel engine if your goal is to go past 80hp then you might be better off with the Garrett GT12 turbocharger because 80hp is at the limits of what the GT06 turbocharger is able to flow. And for a Diesel engine you need even more air to get to the same HP level as a gasoline engine.

Hello!

I would like to use the GT06 on a single cylinder engine which is build for Formula Student series. On the test bench I would like to use a separated oil system (not the engine's oil system) Could you tell me what is the minimum value of the oil flow rate? I need to know it to decide which pressure regulator valve is suitable for the system. Thank you!

Hello, a journal bearing turbocharger like the GT06 need at a minimum 1.5 bar oil pressure. I would recommend 2 bar oil pressure to be on the safe side if the engine is going to be driven hard. Good luck with the build!

hi JD , can i use this gt06 for my ninja 150cc 2stroke ??

Hello, yes this GT06 turbo should work fine with a 150cc 2 stroke. You might need to do some tests with the exhaust lengths and size to see what works better to get the best performance considering it's a 2 stroke engine you are turbocharging.

Hi

Would these turbos work in a twin turbo design on a brute force 750 atv? Its a two cylinder 4stroke machine

Hi Justjunior02, going with a twin turbo setup would work. However if you have space I would try and combine the exhausts going to the two GT06 turbochargers, that way it might be easier to control the boost pressure once you get everything running.

Hi,

Would this turbocharger be suitable for a two cylinder 800cc engine turning at around 3400 RPM? The application would be a horizontally opposed two cylinder engine, specifically a half-VW. This implies that the exhaust pulses would be evenly spaced, unlike a Vee-type engine. The unmodified engine produces around 28HP.

Hi granpa, yes I think the GT06 turbo should work fine for your engine. But like I mentioned to Justjunior02 earlier with his 750cc engine, if possible try and make the collector as open as possible so the exhaust are able to mix before going into the turbo. That way you will get a more even pressure in the exhaust and it will make it easier to control the boost pressure.

Thanks JD. Just to be sure I understand what you are suggesting, this would be a single turbo, with the two exhaust pipes combined before entering the turbo, with a volume in the exhaust system prior to the turbo made fairly large so as to dampen the exhaust pulses somewhat so as to even out the pressure changes between the exhaust pules. Does that sound like what you are describing?

Hi grandpa, yes exactly like that, the correct term would probably be a merge collector type exhaust. The turbine housing on the GT06 have a very different type flange and inlet compared to other turbochargers so making it a real merge collector would be hard to do in a simple way, but if you can even out the pulses before the turbo a bit I think it would help, especially with big cylinder engines. Small engines won't have this problem.

Similar to what is shown in this picture.

www.burnsstainless.com/images/technology/turbosandrail4-lg.jpg

Now for a really basic question about reading a compressor map, sort of "compressor maps for dummies" question. When it refers to "corrected air flow" does that mean the air flow consumed by the engine with the turbo installed or for a naturally aspirated version of the same engine? I have searched high and low on the internet for the answer to this simple question and have not found it. Of course, the answer would make a huge difference for how one would go about finding the correct size of turbocharger.

Thanks.

Hi grandpa, most turbocharger manufacturers are very secretive when it comes to turbo compressor maps and testing. Some like Holset do not even give out any information like compressor maps to the public.

Garrett most likely use something like a Turbocharger Air Flow Bench for their testing like seen in this video, so the turbo is never really connected to an engine www.youtube.com/watch?v=Q8CR-NwxXE0

Garrett does however give an example and explain corrected air flow.

When plotting actual airflow data on a compressor map, the flow must be corrected to account for different atmospheric conditions that affect air density.

Example:

Air Temperature (Air Temp) - 60°F

Barometric Pressure (Baro) - 14.7 psi

Engine air consumption (Actual Flow) = 50 lb/min

Corrected Flow= Actual Flow SQR([Air Temp+460]/545)/ Baro/13.95

Corrected Flow= 50*SQR([60+460]/545)/ (14.7/13.95) = 46.3 lb/min

Now if we do this very simple, for your 800cc engine you said it makes 28hp at 3400 rpm, so that means the engine is moving around 3 lb/min of air by itself at that rpm give or take, and with the same equation 3*SQR((60+460)/545)/(14.7/13.95) = 2.78 lb/min

So looking at the compressor map with 2.78 corrected air flow (3400rpm on the engine) you are not at any risk of surge if you stay around 1 bar boost (turbo spinning 240000 rpm). You can follow the 240000 rpm line on the map and you see that 6 lb/min (or around 60hp) is possible.

Here's a quick video that explain a bit more details about how to read a compressor map. And I'm sure there are a few more that gives even more details with math about how to calculate the correct turbo size.

Turbo Compressor Map Explained [GO FAST BRETT]

https://www.youtube.com/watch?v=Mzia8smn9rc

Hello!

I have a two-stroke motor bike 500cc.

I will make it a turbo, and I want to target 100-120hp

what turbo would you suggest?

(it goes without saying that it is going to be like that intercooler, Fuel Pumps, oil pump)

Hi, a two stroke 500cc engine will be much more like a 1000cc 4 stroke. So I would suggest you look at the Garrett GT1241 turbocharger or the GT1544 turbo. Both should be able to give you 120hp. But considering if your powerband is now something like 8000-12000rpm I would go with the GT15 turbocharger. The GT15 turbo will be able to hold the boost pressure high even at higher rpm.

But not too many people are turbocharging two stokes so I can't say for sure what happnes when you remove the expansion chamber exhaust and add a turbocharger to two stroke engine like that.

excuse me, two-cylinder I wanted to say.. :) four-stroke is the engine.

thank you very much for your answer!!

four-stroke

Hi Bill, well in that case you should look at the smaller Garrett GT1241, as the GT06 turbo won't give you 100hp, it would only make close to around 80hp max. The GT12 is the better option then if you want 100+hp and I'm sure 120hp is possible.

Thanks for the help!

one more question, if we went to GT1544 would we fall great?

Hi Bill, the GT1544 have a bigger exhaust housing so it would take longer to start to build boost on a 500cc, and the powerband will be smaller because of that also.

I'm looking for a turbo for a 1liter diesel engine turning 3100 rpms. Would this turbo work?

Hello Chad, yes at 3100rpm your 1 liter diesel engine will be flowing around 3.22 lb/min air. A quick look at the compressor map, an this GT06 turbocharger would work.

will this work on a Kawasaki GPX250R and what other mods will I have to do to make this work

Hello Smoke, yes the Garrett GT0632sz should work well on the 250cc Kawasaki engine. The 12.4:1 compression ratio is a bit high for boost, so I would fit double head gaskets to drop the compression ratio. But this depends on how much power you want and how much boost you need. But you are looking at around 0.8 - 1bar boost to get around 80hp on the 250R engine.

If the bike have fuel injection you would need to either fit an aftermarket ecu and bigger injectors. Or you can leave the stock ecu in place and get something similar to the RSR AIC400 Additional Injector Controller https://www.rbracing-rsr.com/rsraic400.htm

If you have carburetors you would only need to fit something like the Thunder PowerJet https://thunderproducts.com/product/thunder-powerjet/ and that will solve the extra fuel needed to run a turbo.

Hey JD how can i contact you do you have a facebook profile i want to show you my engine and tell me some information about the small turbo.. thanks

Hi Nicks, sorry no facebook.

Want to run on 2017 Kawasaki 300 ninja re-sleeved to 345cc. What exhaust length do you recommend for max top end HP(Land speed racer) and do I need higher pressure fuel pump. Running Power Commander with ignition module. Can add turbo pressure monitoring. Any suggestions gratefully accepted. Thanks

Hello, a good start for a turbo manifold would be to have equal lengths and around 550mm / 22 inches. For a land speed racer where you want max top end power you could even go with 750mm / 29 inch lengths if there is room. However it really comes down to the engine, and no engine is the same. So it's best to try different lengths if possible and see how the engine responds.

I'm not sure what injectors the 300 ninja use, or if the map sensor and ECU can read boost pressure. So first you would probably need to figure out a way on how to add extra fuel when the turbo starts building boost pressure.

Sir i have an liquid cooled ktm duke 390 approx 373 cc engine i want to use gt06 on this .bike also have efi in it ,with stock piston an other stuff. It generete 43 bhp does the turbo work on it or my engine will deformed

Sir are you on Instagram 🤓

Hello, sorry no Instagram. The GT06 turbo should be good for you on the 373cc KTM bike. I would expect to see around 70 hp with 0.7 bar / 10 psi boost pressure. And you could probably get to 80 hp but would need to run closer to 1 bar / 14 psi boost for that.

However I would not try and go beyond 70 hp because the rod bearings and crank pin will start to wear down really quick if you are pushing +80 hp. At that power level you can only expect the crank / engine to survive one season of racing before a complete rebuild with new bearings, crank pin and possible piston and piston pin..

So for longevity I would keep the power to around 60-70 hp.

Hi JD ,

I want to use this gt06 turbo on my ktm 390 engine can you tell me what are the problem could come on turbocharging a single cylinder and how bad it affect transient ?

Hello, I would say if you stay around 60-70hp and use good quality oil then you probably will be ok with the normal maintenance like oil, filter change every 15hours / 620 miles as per the KTM recommendation.

With the stock piston you should be fine for 2-300 hours of use. However when you start to push single cylinder engines past 80+ hp and race them then you might expect the piston to only last 50 hours and the same with bearings, rods etc.

So you can see how that extra power can really start to wear on a engine simply because it was not designed to handle that power level to begin with.

Hello, hope you can help. I have Harley XR1200, fuel injected with ThunderMax ECU - can autotune etc.

Would 2 of these be suitable, each one mounted very close to exhaust from head then both feeding into a plenum, hopefully at least 2 litres volume to compensate for being a twin.

My other project is a 1948 500cc, max revs 6k and can fit fuel injection. Hoping one of these would work as intended.

My math for plotting compressor map for each of these projects has me stumped so far.

Thankyou for helping my 2 bike projects

Hello, twin GT06 turbos would work pretty well. I guess your XR1200 puts out around 80hp so running with twin GT06 turbos you should be able to support around 160hp at around 1 bar / 15 psi boost.

Because the turbos are the smallest turbos out there you would be running them at the far right of the compressor map on your engine so it won't be the most efficient setup. I can't really say how quick they would spool because that also depends on how short you can build the exhaust, and also a bigger plenum will also take a bit longer to fill so that also comes into play with response and spool. But I would guess you should have them spool around 4-5000rpm.

You don't have many options considering the next size turbo is the GT1241 and that would be too big to run with twin turbos. However if you want to you could run a single GT1241 turbo also.

For the 1948 500cc the GT06 would be the best option and I think you should have no problems spooling this turbo on that engine. You won't need fuel injection but it does make fine tuning easier.

Hola. Tengo un fiat 126p del 1985 con su motor original 670 cc y 24cv. Funcionaria este el GT06 en el o algún otro que sea bien pequeño. Gracias desde Cuba

Hola. Tengo un fiat 126p del 1985 con su motor original de 670 cc y 24cv. Funcionaria el GT06 en este motor. Gracias desde cuba

Hola, yes the GT06 would work, expect to get around 50cv with 1 bar / 15 psi boost pressure.

Where can I get information about GT06 installation, especially oil lines(inlet vs outlet) and what pressure spring comes standard in the waste gate.

Thanks

Hello, unsure about the oil lines but the wastegate should be set to around 7-10 psi as standard.

Could I use this turbo on a Vespa gts 125cc?

Hello, it should work on a 125cc Vespa but expect a bit of turbo lag before it starts to build boost.

Cm250 custom?

Hello, on a twin CM250 engine you would probably start to get boost around 7-8000rpm so if you can rev the engine to 10-11k rpm and get some high lift camshafts it would be better.

Hello I am in the process of building a 1981 Kawasaki kz440 A2 engine rated at 40hp@ 8,500rpm. I have a compression ratio of 9.2:1. I intend on doing a full digital ignition and sensor electrical system, efi, and I am stumped between 2 turbos. Which would be better for my application the GT06 or the GT1241? I dont have any intentions of building the bottom end if I can help it. I also want to try and use just an oil cooled and fed journal bearing system. Any recommendations? Thank you

Hello, if you are not going with an intercooler setup or running E85 fuel I would try and keep the boost pressure to around 10 psi / 0.7 bar max on your compression ratio. If you are going with the GT06 turbo and need to limit the boost pressure then you could expect to see around 65-70hp with the GT06 turbo and have good spool.

However if you go with the GT1241 and run the same boost pressures you should be able to get 80hp without much issues. However the GT1241 turbo will be a bit slower to spool and you might end up having to rev it to 6000 rpm to get into boost if you can't run short exhaust runners.

Overall I would go with the GT1241 turbo because it's cheaper and easier to find, and then spend some time and build the engine so you can rev it to say 9-10.000 rpm. That would give you a nice powerband with the GT1241 turbo.

Mr JD,

I'm in the process of building a turbo GL500. 9500rpm, 70-75HP, 1.5 pressure ratio, and 8lb a minute.

This falls inline on the RHB31, GT1241, and GT1544.

At peak RPM, the RHB31 sits about 65-66% compressor efficiency, GT1241 about 67%, and the GT1544 at about 74% efficiency.

The 2-1 manifold will be .8" pipe of as short and as equal length as I can make it giving the space. It will be intercooled.

The compressor maps come on at different Pressure ratios as well, at the bottom of the map. the RHB31 starts at 1.2, the gt1241 at around 1.4, and the gt1544 at around 1.2. Am I mistaken in my initial though, to believe that he gt1544 would be best suited for this application? I am more concerned about the mid-range power, than having the power all at the very top end of the range. I would rather the turbo spool and build boost low and have a higher efficiency through mid range, than have peak efficacy at the top of the revs. It is a street bike.

They stay at or above 65% efficiency at 1.5 pressure ratio as follows:

RHB31 from ~3-8 cfm

GT1241 from ~4.5-10.5 cfm

GT1544 from ~4-11 cfm

Given that the bike will mostly live in the mid-range power, am I mistaken by retracting my previous assessment that the GT1544 would be the best suited turbo, and reassign the rhb31 to best suit my needs?Given that my peak CFM will be 8psi, and it will mostly live in the middle of the revs - and since the RHB31 is above 65% efficency from 3-8cfm,at my desired boost level, that this turbo would be the best selection.

If the RHB31 will spool and come to peak pressure of 1.5 ratio, and 3cfm low in the revs, say 3500rpm, and maintain that 1.5 pressure ratio through 9500 rpm - it will start at 65% efficiency, and sweep through 68-70-72 and back down again ending at 65% efficiency. Though I'm not sure how my theory will translate into real world. I calculated all of this with a post intercooler charge temp of 120deg. The engine is 10:1 compression and in stock form, which is why I would like to stay at a 1.5 ratio.

Thank you for reading my saga,

Matt

I would like to correct my previous posting. I typed CFM rather than Lb/min. It's been a day....

Hello Matt, because you would need to run a pretty long manifold on the GL500 bike I would go with the turbo that have the smaller turbine size to help spool. In this case the GT1544 turbo have a 42.2 mm turbine wheel and the GT1241 have a 35.5 mm turbine.

So even though the turbos have similar flowing turbine housings the GT1241 would still be a bit quicker to come on boost due to it having a lighter turbine and compressor wheel assembly.

The RHB31 from what I can see also have a similar size turbine to the GT1241 turbo however it does seem to struggle to provide the needed airflow at your max boost pressure, and you would be lucky to get 8-90hp from that turbo. However with the GT1241 you should be able to get to 100hp without much issues.

Also if you really need to run an intercooler try and get a small one and keep the pipes short, as this will also affect spool up times.

Hi, I'm on the way to turbo charge a 4 in line 1905 cc 16 valve engine with two GT1241/z an draw trough carburetor, is it a problem with the shaft seal type on the GT1241/ turbo ? Is the GT 1241/z equiped with a carbon type shaft seal on the compressor side ?

Thanks for your answer.

Hello, the GT1241 does not have a carbon seal fitted and is the regular journal bearing type turbocharger.

However with good bearings and seals fitted you could still use the turbo if you either run a recirculating blow off valve or the regular open type blow off valve fitted between the carburetor and turbo that stay open when the engine idle. This will limit the vacuum at the turbo. If you still have oil getting past the regular seals you can fit a restrictor on the oil line going to the turbocharger, this will reduce the oil getting past the seals. Only make sure you have enough oil going to the turbo so you don't run into problems.

If this still becomes a problem you could contact melett.com and ask for carbon seals, they have carbon seal kits for the older T12, T2, T25 and T28 turbochargers and many others.

http://www.vaglinks.com/Docs/Catalogues/Melett.com_Garrett.pdf

However for the GT12 turbochargers repair kit 1102-012-751 it looks like Melett only have the regular journal bearing kits available.

Thanks for your answer :-)

Hello, JD i am after some advice on this turbo, i have a Yamaha R125 (125cc) and plan to turbo the engine, will this engine have enough exhaust gases to spool the turbo up? i have heard the gt06 is the smallest turbo to date, as the r125 only makes 15hp. i would understand I'd need to make a very short manifold straight to the turbo, i also plan on getting a tuning module to set the fuelling. i also need a O2 exhaust sensor to map the bike for the turbo.

Hello Shaun, with 15hp you are going to need to rev the engine very high for the turbo to start to spool. I would do a high lift cam and 180cc kit or similar at minimum. With that and a good setup you can expect the turbo to start spooling around 8000 rpm. So to get a good powerband you would need to rev the engine out to 10-11k.

Hello JD, we are student and currently trying to build a model with this turbo. Do you know at which speed the turbine is running on the turbine mass flow map ?

Hello, I can't confirm the exact numbers however I suspect the speed is around 150.000 rpm starting at 1.5 positive turbine pressure ratio with the max around 300.000 rpm at 3.5 turbine pressure ratio. Most efficient around 200.000 rpm.

Hello JD, do you know the wastegate diameter of the GT06 ?

Hello, the EGR port on the GT06 turbo housing is 15.5mm however I don't see a wastegate diameter. But I bet the wastegate is close to that size also. I have now updated the page with some more GT06 turbo dimensions so you can all have a look.

Direct link

https://1.bp.blogspot.com/-6wNxGxHgFAM/XkrvLlCNTlI/AAAAAAAAEbs/oa379rFc2GwKyJJb-PEXXKNm2qiCw7BDACLcBGAsYHQ/s1600/Garrett%2BGT06%2BTurbocharger%2BGT0632SZ%2BMeasurements%2Bin%2BMM%2BTurbo%2BFlanges%2BDiameter%2BHoneywell%2B1280x1474%2Bwww.TurbochargerSpecs.Blogspot.com.png

Hello,

I need some advice about upgrade turbo on my bike Suzuki 150cc FI . I am planning to use RHB31 turbo on my bike( keep stock internal engine parts) and my target is 25-30HP (stock bike is 19HP).

Would you like to recommend the boost I can run so that can reach my target ( 25-30 HP)?

Regards,

Hello Tony, you should aim to run around 8-9 psi / 0.6 bar boost if you want 30hp. For 25hp you would only need to run around 5 psi / 0.4 bar boost. The stock wastegate should be set to around 10 psi from factory and that would give you closer to 32hp.

Thanks for your recommend .

I need adding a intercooler for using fuel pump A95 , is that ok ?

Hello Tony, you should be safe without an intercooler if you keep the boost pressure around 7 psi. If you want to go higher I would recommend you mix in an octane booster with the fuel. A cheaper alternative to octane boosters is to try and get some Toluene, it will also help raise the octane and prevent detonation to some extent.

Hello JD,

Compression ratio on my bike is 11.5:1 ( stock ) , it will be safe with boost pressure round 7psi .

Thanks.

Hello Tony, it should be fine for you because the boost will only come in at a high rpm range so there is less chance for detonation. But you need to make sure you have the right air fuel mixture so there is no chance of running lean on boost. It would be better to run a rich fuel ratio. Also if you want you can use 2 headgaskets on top of each other to drop the compression ratio. Then you would not need to worry about running higher boost.

Hello JD,

Thanks for your advance . I will set up it turbo and let you know the result after I run it .

Hello JD,

I have a Mitsubishi mt372. Its a small diesel tractor,the engine is a 2 cylinder 700cc 15hp 2700rpm.

I'm using it to clear snow in my driveway and ot could really use some boost!

Do you think the gt06 is my best option?

Thank you for sharing your knowledge

André

Hello André, the GT06 turbo would be a good option considering the turbine housing is well suited for a twin cylinder engine. I can't really say how quick it would spool up but you can expect around 25hp with 0.7bar / 10 psi boost.

Hello JD,

I have installed turbo RHB31 on my bike 150cc and tested but the result was not good .

The bike had less power at high rpm , it could not reached redline (max 13000rpm) at 5th and 6th gear .

Full boost 0.4bar from 7000rpm

air intake temperature is 60 degree C

Run AFR 11.5 with WOT

I changed valve spring .

Please help me to see it .

Do I need replace ignition system as coil and spark plug ?

Regards

Hello Tony, first I would try running less boost or check the spark plug gap and make it smaller around 0.4-0.5mm and see if anything changes. If the spark is getting entierly blown out, it should almost cut out the engine when the turbo hits full boost. Also a rich AFR mixture is harder to ignite, so if you are sure the AFR gauge is showing the correct mixtures you could try and run a bit leaner mixture on WOT and see if that helps.

Also if possible you can try retarding the ignition a few degrees and see if the engine starts to rev out better.

Thanks for your suggest.

For you, air intake temperature is roughly 60'C is an issue for air charge ?

Hello Tony, it is high but as long as you don't go over 60c it should be fine. You could start to run into detonation and melt pistons if it goes too high. So you should try and get the inlet temp down to around 40-50c if possible. You can lower the temp with a tiny amount of methanol / ethanol or water injection into the turbo inlet.

That said I'm not sure how the bike ecu likes 60c temps, it could be possible that it starts limiting power when it sees high inlet temps, and that's why you can't get to redline in high gears.

Hi, would a 125cc single cylinder with 9.2-1 compression and rated 11 hp at 9200rpm be able to spool up a Gt06? Id be satisfied with 5psi. (turbo lag is just a bonus!)

Hello, if it's a 4-stroke 125cc with a stock cam and ports you should be spooling around 8000rpm if you can keep the exhaust runners short. It would give you around 14hp. But if you want a bit better spool and you are not going over 5 psi boost, then you could go with a big bore kit and even higher 10.0:1 compression also to help with response. It should get you close to 20hp with 5 psi and a good tune.

Hi, I see that you've answered a few questions about a set up on a Kawasaki 250cc ninja, but I still have a question. If I I run e85 without reducing my compression would I still be running a risk of detonation? And if so would an intercooler help?

Hello, it is very risky with that high compression, you could probably run the Kawasaki 250cc ninja on low boost and E85 alone. But it's hard to say when detonation would start to become an issue because there's too many factors that come into play. But having even a small intercooler would definitely help. To be on the safe side it's better to have lower 10.0:1 compression and E85, because if you can't control the boost well it's very easy to run into detonation on a high compression engine by mistake.

Good afternoon JD,

I'm considering this turbo for three engine applications:

Honda CMX500 with 471cc parallel twin engine

Kawasaki Vulcan S650 with 650cc parallel twin engine

Suzuki Carry kei truck with 653cc three cylinder engine

I'm aware the latter two have larger engines than recommended but it appears this turbo works up to 90hp or there abouts, what are your thoughts on Garret GT0632SZ for these purposes? From a packaging perspective its small that it would work great on the bikes, Or should I move up to the Garrett GT1241 or even a Borgwarner K03 for the latter two?

Thanks

Hello lelilulilo, I think the GT0632SZ turbo would work best overall for all engines. Even the bigger 650cc engines because peak power is fairly low at around 5-7000rpm. For the Kawasaki you could go with the GT1241, but only if you really want to have more top end power and perhaps are considering raising the redline to around 9-10.000rpm. With the Garret GT0632SZ turbo it would spool fast and you would get more low end power and torque.

Thanks for the reply. Really appreciate it . Have a good one.

Hey, I'm planning to get the GT06 turbo for my Royal Enfield GT650, also have a parallel project with another Royal Enfield GT650 which has now been bored out to a 865cc, do you recon, this turbo would help this project.

Hello Rohit, on your GT650 the GT06 turbo would be a good choice, the stock 9.5:1 compression is a bit high to run high boost safely but if you keep boost pressure around 0.8 bar / 12 psi you could get around 70hp. With some porting and a good cam you could probably see around 80hp with the same amount of boost.

For the big bore GT650 you could go with the GT06 turbo also and get better low end torque but you won't really get any more than 70-80hp due to the GT06 compressor would become a restriction to airflow.

It would be better to go with the GT1241 turbo but only if you are looking for top end power. With the big bore kit and running 1 bar / 15 psi boost you could see around 120hp. But again I would be careful not to go much higher in boost due to the 9.5:1 compression ratio.

And if you are running higher 11.0:1 compression, I would really make sure to never go over 0.7 bar / 10 psi boost and only run Ethanol E85 fuel instead. If you can't get E85 or drop the compression you could do ethanol or methanol / water injection.

Thank you so much JD ! Truly appreciate it...

Hi, looking at boosting a 4 stroke, 4 cylinder 250cc that produces peak power at 14000rpm (max 19500), 45hp. Im guessing this turbo would be good fit?

Hello akeizm, the GT06 turbo would be a good choice however if it's a Honda CBR 250R engine that have 11.5:1 compression you would really need to drop the compression to run higher boost.

If you can't drop the compression you could still get around 60-65hp but I would not go anything above 0.4-0.5 bar / 6-7 psi boost max. To be on the safe side you should consider running E85 fuel or doing water / methanol or ethanol injection.

That said if you could drop the compression down to around 9.0:1 you should be able to get around 75hp with 0.8 bar / 11 psi boost.

Hi JD,

Thats correct. Apart from custom pistons lowering compression would be difficult (gear driven cams so thicker head gasket wouldn't be possible?). Anyway, I was looking at running low boost (so stock spring at 7psi) with an intercooler. Currently working on EFI too so tuning will be easy compared to carbs.

Hello akeizm, you could try and lengthen the timing chain with one or two links, not sure how much adjustment is available on the tensioner but it could be enough to run double head gaskets or a thicker one. But if you stick to low boost with intercooler you should be OK, and running EFI will also help a lot with tuning.

Hi JD. Those engines are gear driven (no belt or chain). Im not far off trying my efi setup so if that goes to plan, one of these little bad boys will be going on

Hi JD,

I have an Aixro (Wankle) rotary cart engine with a 7000 RPM rev limit and 293CC displacement. It is a 4 stroke at about 36HP. I would like to boost this to 60-65HP wonder if the GT06 would work? How much boost would you recommend? Is there an After market EFI you could recommend? What carb size should I be looking at?

Hello Skyedancer, rotary engines spool turbos very well so the GT06 turbo should work fine for you. If you have a tuned engine that makes 36hp with a 7000 rpm limit you might only need around 0.7 bar / 10 psi boost to get 60hp. However if you are limited to 7000 rpm on the engine and it only makes around 30hp at that rpm you might need to run a bit more boost around 1 bar / 15 psi to get to 60-65hp.

Going with a EFI setup would be recommended because the seals in rotary engines are very easy to damage if the engine start to knock during boost. Some good ECUs would be Vipec or Link both feature knock sensors inputs and tools. Link ECU have a thing called Knocklink that is a visual knock warning tool that requires no setup. However both are a bit expensive, an alternative would be a simple megasquirt ECU however with that you need to have a MS3 Knock Module Kit installed in the ECU to work somewhat, but not really in the same caliber as the other options.

With a carb setup you would want to go with a smaller size instead, because it is better to have high air flow speed to help with fuel / air mixing on a turbo setup. You can try with the stock carb setup and if you have a hard time tuning the mixture you can go a bit smaller.

Hi there, I have a Royal Enfield C5, 500cc low output, (27.2 hp,) low RPM (5250 soft redline,) single cylinder, air cooled motor. I’m trying to figure out my options for turbocharging this bike. Is low compression ratio (8.5 t:1,) It has a very rudimentary fuel injection system, so I don’t know if or how I can modify it enough, or maybe I should just do A flow-through carburetor set up in it. I’m looking to try to get 45 hp out of it, but I’m worried that that might be close to 15 psi, and since there’s no room for an intercooler. I’m looking To increase the bikes overall drivability, especially at highway speed’s, rather than all out maximum power. Any insights or advice that you would have would be greatly appreciated

Hello Dvcycle, if you like to keep it simple you can do the flow-through carb setup. But to make tuning easier with a carb, try and find a carb that's not too big. Around 25-30mm carb should be a good start. With the GT06 turbo to get 45hp in the engine you would need around 0.7 bar / 10 psi boost. And close to 1 bar / 15 psi boost to get around 45whp. If you stick to 0.7 bar / 10 psi and have a good tune you should not need an intercooler, however on very hot days it could cause problems. So I would advise you to also inject a small amount some water / methanol on boost or use Ethanol fuel if possible.

Thank you so much for your advice! How is water/methanol injection accomplished?

In an unrelated question, what do you think about these very inexpensive VZ21 Mini Turbochargers you can buy on eBay?

Hello Dvcycle, you can do what's called pre turbo water injection. With that setup you put a small nozzle at the inlet on the turbo and supply some water / methanol from a small 6-12v electric pump so you get a fine spray. With that setup you would need to turn on the pump by hand, or use a low pressure solenoid to trigger when on boost. You could probably also make it work with a adjustable ball pressure relief valve and have the boost pressure overcome the spring to inject the water but that might take some adjustments to make it work.

But if you want to make it really simple you could do a venturi pipe between the air filter and turbo inlet and have the water / methanol hose connected there. There are several ways to make it work.

Similar to this picture but a bit smaller in size:

https://www.researchgate.net/publication/330361050/figure/fig1/AS:714966386614276@1547472678843/Venturi-gas-mixer-design-with-dimensions-mm.jpg

The VZ21 turbos seem fine but there are a few reviews of oil seals gone bad. I have not heard of any real bearing failures so for small engines they are not that bad. If the compressor maps found online are correct they are bigger in size and flow more air and support around 100hp at 10 psi boost. So they are bigger than the GT06 turbocharger and in turn would spool up slower.

Thank you, you have an amazing wealth of info. I’m so glad you choose to share it!!

Hello:

I have a honda rebel 250CC that currently has a GT15 fittred but it will not build any boost on the dyno?? we've have these turbos on go carts with 5.5 hp and they build boost. wondering if its just to much turbo for the bike?? would you recommend a gt12? or go with this GT06??

Regards,

Max

Hello Max, I'm surprised you got GT15 turbos to build any boost at all on 5.5hp go cart engines. The GT06 turbo would be a much better option for the 250cc Honda engine because it's turbine flow is about half that of the GT15. With a GT06 turbo fitted you could see around 45hp with 1.6 bar / 23 psi boost. However if you can't run an intercooler or use water / methanol injection I would stick to around 1 bar / 15 psi boost that would still give you around 35hp.

As for the GT12 it is not that much smaller than the GT15 either and if you are not looking to make 100hp I would try and find either a GT06 or a HB31 turbo could also work.

Hello JD, i thinking of blow through carb setup with my Honda XR400R with big bore 435cc. Head intake is BIG ported and exhaust left original. Stage 3 cam, Mikuni BSR42. Compr ratio spot on 11:1. Got a piston that lower it to 9:5. I really want to use the simplecity of original cdi (its not retardable) reving i belive to 8500rpm. I am intrested in non restrictive setup with a good driveable LOW end pickup. Whats you thoughts here, what turbo setup on a aircoold engine? Gas 98 octane. Could i expect to ruine aluminium carb/engine valve seats etc with E85?

Hello OlaMGlader, the GT06 turbo should work well however I would not leave E85 sitting in a aluminium carb for a long time because it will corrode the bowl over time. Things like the head and valves are no problem with E85 because E85 evaporates very fast in the open and even faster on a hot surface. One thing that can happen if you run a very rich mixture or have a cam that blow back is a buildup of red deposits of E85 in the intake and ports. So it's best to run some 98 octane from time to time to clean the engine of these deposits.

If you live in a colder climate one solution is to have a small tank with 98 octane that you can switch over to for cold starts and have it running on 98 octane for a few min before turning off the engine to flush E85 from the carb. That or you could just make sure to drain the bowl if you know you are going to leave the bike sitting for a long time.

Thanks for the reply, I see that now. My turbo is mounted under the seat inside the frame of my 250. We have determined that the gf15 would built boost if it was mounted right out of the motor. So after looking the hb31 and gt06. The manifold style mounting plate and angle of the gt06 wouldn’t really work for my bike. I went with a TRITDT TD025L-8T. Very comparable size, and applicable to same engines for 1/2 the $$. As well as similar mounting positions to my gt15. Have you heard much about them or that specific turbo

Itself?

Hello Max, well that explains a lot. To give the turbo a chance to spool on smaller engines it's always important to try and have the manifold length as short as possible.

The TD025L-8T is still on the bigger side for your engine, it's more suited for engines around 500cc. It's going to take twice the rpm to get it to spool on a smaller 250cc engine. The compressor size can supply air for around 100hp so it is a bit smaller than the GT12 turbo.

So going by that you can expect it to start spooling around 6-7000rpm, and you should see around the same 45hp with 1.6 bar / 23 psi boost. You should try and get it mounted closer to the engine or use smaller diameter pipe as it would help.

If you can't get it mounted closer or still have problems with spooling you should try and get the engine to rev higher with some cylinder head porting and get a high lift cam with some racing valve springs.

Good piont, from my research the GT06 flange style wouldn’t work for my bike and would

Require a lot more fab work and the application ccs seem to be comparable. I mean the bike does move the gt15 but not enough to make any significant boost numbers. I’m hopeful the tritdt significant smaller size will do the trick. Not looking to make but 5psi of boost for some weekend fun. The GT06 seemed to be similar sized to the tritdt, the GT06 states 100cc-500cc or does it go based mainly on the hp range?

Hello Max, please tell me at what reference pressure and temperature the turbine map is being built

Hello Max, there does not seem to be a lot of info on the tritdt turbos so it's hard to say how similar they are. Garrett do go by turbine and compressor flow to determine the suitable engine sizes for turbos. Where a 500cc 4-stroke with a GT06 turbo fitted usually would only give a small increase in power on boost, but the turbo would still be big enough to not become a restriction to air and exhaust flow.

i have a cb 750 four cylinder for stroke bike that i want to turbo. currently makes around 60 hp at 7,000 rpm would like to run 5 to 7 lbs of boost to make 80 -100 hp or so. what turbo do you recommend? has 4 into one exhaust

Hello, the GT06 is on the smaller size for you and you should instead look for the cheaper GT1544 or GT1241 turbos. You should make around 90hp with 0.5 bar / 7 psi boost. And to get above 100hp you would need around 0.7 bar / 10 psi boost.

However if you are planning on making a draw-through carburetor setup then neither the GT12 or GT15 turbos have carbon seals installed. I have heard there is a Hitachi HT10/12 carbon seal that can be retro fitted but I don't have any more info about that.

But you can still make it work without carbon seals, and you can read more about it above from my comment I made back in December 2019.

Hi there I have a Benelli tnt300 which revs out at approx 11,000rpm and produces approx 38bhp ,which turbo would be suitable for a small increase in power ..regards Dave Atkin

Hello Dave, for best spool the GT06 turbo would be the best option for you. You can expect to get around 50hp with 0.4 bar / 6 psi boost. The GT06 should start to spool around 4-5000rpm so it will give you a very good powerband. You would need to run either E85 fuel or do water / methanol injection if you can't drop your 12:1 compression ratio lower. With 9.0:1 to 8.5:1 compression you should be safe to run 0.4 bar / 6 psi boost without any added water / methanol.

You could also try the cheaper option and go with a VZ21 RHB31 turbocharger, however this turbo is much bigger so it might not spool until 7-8000rpm on your bike. You would still get around 50hp with the same boost, however if you also do a ecu remap and raise the rev limiter to 12500rpm it would be a good compromise between cost and performance.

Where can i perchase a gt06 turbo

Hello, you can search the net for the Garrett Part Number: 789997-5001S or the OE Part Number: 571014510101

That should give you many results for brand new and second hand sellers of the GT06 turbocharger.

I see that there is a sale right now to get 28% off on the GT06 turbo if you go to

https://www.turbo-total.com/en/gt0632sz-garrett-turbocharger-789997-5001s-752

At €428.36 including VAT is the cheapest I have seen these GT06 turbos go for new so far.

could i use this on a 11hp riding mower engine

Where & how can i perchase GTO632SZ Turbo...??

Hello, if it's a 11hp 400cc Briggs and Stratton it would be best to try and increase the rpm limit because at 3600rpm it might not be enough to spool the turbo, and if it does start to build boost you would constantly be on the rev limit of the engine.

I would like to buy a 2020 Kawasaki ninja 250r Brand new. I want to know what turbo and all other parts i need to plug n play.what all do i need?

Hello, I don't see any confirmed power figures or engine specs for the new 2020 Kawasaki 250r ninja as of yet. However if true the engine is claimed to have around 50hp at 15-17,000 rpm with Ram Air. That said the GT06 turbo is a bit on the small side for the new 250r ninja and you would only get around 20hp more or around 70-80hp with the GT06 turbo fitted. It's a good option only if you would want more low end torque and a small boost in power.

The GT1241 turbo would be a better option if you are looking for more top end power. You could get around 100hp at 1 bar / 15 psi boost. And you could get around 120hp with 1.4 bar / 20 psi boost.

However this would only be possible with low compression pistons fitted to the engine as I am sure the 250r ninja have very high compression as stock. You would be wise to fit aftermarket connecting rods while the engine is apart. As I don't know how strong the stock connecting rods are made.

Then you would need all the things like custom plenum chamber, pipes, intercooler, exhaust etc. If the turbo can't be fitted lower than the sump you would need an electric oil scavenge pump also for the turbo. And if you wan't to go EFI, you need an aftermarket ECU with injectors and fuel pump. I'm sure the 250r generator can't supply enough power to drive all the electrics without draining the battery, so either go with a more powerful generator or you can have a 12v high capacity Lithium battery fitted and charge it up before you go for a drive.

That said there won't be a plug n play solution to turbo the 250r ninja unless someone makes a turbo kit for the bike.

Edit: I meant to say "If the turbo can't be fitted HIGHER than the sump you would need an electric oil scavenge pump also for the turbo."

Hi what turbo can I just bolt onto a chery qq 800cc with stock internals, and then just add a little tuning and ofcouse oil feeds and all that

Hello LDB, the GT06 turbo would be a good option for fast spool. You should get around 70hp with 0.8 bar / 11 psi boost and around 80hp with 1 bar / 15 psi. I'm not sure how much the stock internals can take. Things that could fail over time or with a bad tune would be the head gasket. I would recommend you fit a small intercooler to keep the inlet temps down. If you want more power a GT1241 or similar size turbo would give you around 100hp with 1 bar / 15 psi boost. But I don't know if the engine can take that much power.

hey would it work on 8 horse power diesel

Hello, it depends on how big the engine is and how high you can rev it. You can try but chances are it won't spool up well on a small low power diesel engine.

What are your thoughts of adding this turbo to a stock Suzuki DR200S?

Hello JTweezy, you could get around 30hp with 0.5 bar / 7 psi boost. But you should not expect much gain at the low end because the small DR200 engine is going to have a hard time spooling the turbo at lower rpm.

You could get around 40hp with 1 bar / 15 psi boost, but that would need an intercooler fitted to be on the safe side. And also at that power level I'm sure the big end bearings would start to take some damage over time..

Hey there I have a ninja 400cc streetbike 2 inline cylinder and revs out at about 13,000rpm and does have a customizable ecu tuning kit. Honestly everyone is telling me it's crazy and I will blow my engine but I don't believe them and want to prove them wrong. My bike is super modded out and there isn't anything else I can do to it at this point so I am left with this idea of a turbo. I have approx 65hp now what would be the ideal hp gain I could expect from this turbo? And would this be a good turbo to use in this application?

Hello Ninjalou, because the GT0632z turbo is close to its limit at around 80hp you would gain more low end power with it fitted than top end power. However if you instead go with the GT1241 turbo you could get around 100hp with only 0.5 bar / 7 psi boost.

The engine / bearings etc. should be fine if you stay around 100hp but you could get around 130hp with 1 bar / 15 psi boost. However at that power level I would think the bearings would start to have a hard time and wear over time, so you would need to do regular rebuilds.

Either way even if you only run low boost, you would need to either drop the compression ratio with some low comp pistons. Or one alternative would be to run two head gaskets or use a thicker head gasket if possible that does the same. And if possible switch to E85 fuel. Because if you now have 11.5:1 compression you would even with low boost run into detonation pretty fast.

Ok well no I wouldn't just want to run low boost and a 100hp is a very reasonable amount of hp I am looking for. So the second turbo would be something of a better fit. My engine is basically a half of the gsxr 750 Motor. 2 cylinders 400cc running around 65 hp fully modified. So if I could realistically get 100hp from my engine with out abnormal engine rebuilds I would be thrilled any other suggestions for me?

And honestly if I have my engine built out beforehand like I'm talking new valves new springs new pistons port and polish the heads new aftermarket cam with a higher lift manual cam tensioner along with other components that get redone when you build an engine out with that allow me to run a little bit more out of it without having to worry about you know as much of a deterioration with the engine because from what I saw on the specs on that turbo it could run around 54 horsepower from it and if my bike's running 68 horsepower alone beforehand if I'm put about 54 into it I'd be around 122 horsepower with a fully bill engine plus the turbo build you think that would be reasonable enough to not have to blow through engines left and right

Hello Ninjalou, if you do a rebuild with some low comp pistons and drop the compression to around 8.0:1 you would be pretty safe in terms of detonation. However dropping the compression also makes the engine produce a bit less power. So you are not going to have the full 68hp to begin with.

Can't tell exactly how much but even if you lose 10hp or the base hp drops to 55hp you are still only going to need around 0,8 bar / 12 psi boost to get to 100hp. And that should be a really safe tune with a rebuilt engine. Now if you want to push it to 120hp you would need a bit more boost around 1.2 bar / 17 psi. But that should still be ok if you can get a small intercooler fitted or switch over to E85 fuel.

Ok not bad food for thought 💭 the I really do appreciate it and buddy. Thank you for your time. Have me a good amount of incite into what I think I am going to do for this Build

i am looking to put a turbo on my lawn mower and was wondering if this will work. it is a cub cadet. with a kholer 18 goodnight i love you motor

Hello c753357, the Garrett GT06 turbo would be the best option for the Cub Cadet. But how well it would work that depends on the setup. Try and get the engine to rev a bit higher by adjusting the governor, if you can get it to rev 500-1000rpm higher it would help.

What turbo do you recommend for a yanmar 2tnv70? I have the fuel adjuster backed out where it will black smoke when you snap the throttle. It’s for a Garson tractor I’m building the engine is 0.57L 2 cyl

Hello Daniel Prentice, with the stock Yanmar 2tnv70 the GT06 might work. But I'm concerned it won't build boost well on the stock engine. With the GT06 it would help a lot to get it to spool if you could try and increase the max rpm to 4-5000rpm. With 1 bar / 15 psi boost you should get around 25hp.

What turbo do you recommend for my raider 150cc sir?

Hello, for the raider 150cc you could try the GT06. You should get around 25hp with 0.5 bar / 7 psi boost.

I have a 200cc three wheeler I’m considering throwing a turbo on just for giggles. (YTM200e) would I need to do any additional work to the engine to put this turbo on it? I’m concerned the engine wouldn’t be able to handle it given its age. I plan on putting an intercooler on with an external electric oil pump has anyone got recommendations on those?

Hello Luke, if you stay at low boost around 0.5 bar / 7 psi you could make around 15hp with the YTM200 engine. And that should be safe considering it's at a low 8.5:1 compression already. However if you can get it to spool, that's another thing.

I would try and increase the stock rpm limit because stock these engines only run around 5000rpm. If you could get it to 7-8000rpm, that would be much better. For this small engine a small marine 12v scavenge oil pump should do the trick.

Looking into turboing my 2020 benelli 302s. The gt06 seems like the turbo I'm gonna need, what else do I need in order to get it to function properly? Can I get by with fitting it up with intercooler (no e85 available close by) and running a Dynojet Power Commander or will I need to do more to it? New to turboing in the bike world.

Hello, with 12:1 compression ratio so you would need an intercooler fitted if you can't find E85 fuel. You might need bigger injectors fitted if you want to get the most out of the GT06 turbo but I'm not sure what the flow rate of the stock injectors are so you might be fine.

You would need a set of 300cc injectors at minimum if you plan on running E85 fuel or 240cc on normal fuel.

You can expect around 70hp with 1 bar / 15 psi boost. Only something like the POWER COMMANDER V PTI can handle the added boost with its built in 3 bar map sensor.

The regular Power Commander units only use the stock map sensor and you would then be limited to around 0,7 bar / 10 psi boost. Because the Benelli map sensor was not designed to read boost pressure it would be hard to tune anything above that.

Hello, I want to make honda x adv turbo, the car is 750cc, and the speed is very low. The horsepower on the original wheel is only more than 40 horsepower, I want to make a big improvement, because I don't sell gt12 and gt06 here. RHF4 turbo, RHF3 and RHB31 which is more suitable, compare gt12 and gt6

Hello, the RHF4 turbo should be the best option and give you around 80hp with 1 bar / 15 psi boost. The RHF3 turbo would give you a bit faster spool if you want that, but it can only really give you around 60hp max.

Thank you very much for your reply. If I use GT12 or GT06, can I add more? My goal is to reach 100hp, and the original car's compression ratio is 10.7:1. Be prepared to reduce to 8:1 and increase the turbocharger pressure. Which turbocharger to choose? Can you recommend more models? I try to buy

Hello, you can get around to 90hp with the RHF4 turbo but you would need to reduce compression ratio to 8:1 and run 1.2 bar / 18 psi boost. If you could tune the engine and do some cylinder head porting and get it to 45hp you could reach 100hp with the same 1.2 bar / 18 psi boost.

Hello, I’m considering to put a gt06 on a Yamaha xmax 300cc. Would it be worth it and which potential could I expect?

Hello Motorscooter, the issue with the Yamaha Xmax is the high stock 10.9:1 compression ratio that is going to limit the boost pressure you would be able to run. However if you limit boost pressure to around 0.3 bar / 4 psi boost then you could make around 35hp or close to 10hp more. But if you can drop the compression ratio you could even make around 65hp with 1.5 bar / 21 psi boost. And you would also need to make sure the fuel injection can handle the added boost pressure.

Hello JD..thanks for keeping this blog running. Such a valuable information source. We are thankful for this 😌

May I have your inputs please I'm looking to replace the stock turbo on my Mitsubishi 4m40 2.8L diesel engine. Can I use this small sized turbo? Not looking for big HP numbers as the car is mainly for city/highway use. going after quick spool/immediate response. Is it fine if I set up Twins? Any idea at what rpm will I be starting to build boost?

Hello, thank you. With the Mitsubishi 4m40 engine even if you do a twin turbo setup with the GT06 it would not be big enough to allow the engine to breath good at least on the turbine side. You could expect around 80hp and better low end power, but at that point you would probably also make the same power running the engine without turbos. A better option if you are only looking for quick spool would be the GT1241 turbo or a VNT turbo of similar size like the GT1549V or GT1544V.

Hi JD,

First of all, thank you with this blog, you're providing a TON of useful and hard-to-find information.

I am working on a personal project, a turbocharger jet engine, and I was wondering.

For the GT0632SZ turbocharger, what mass flow of oil is necessary to cool / lubricate it efficiently at maximum speed (e.g. 300,000 rpm) ?

I read somewhere that the oil pressure should be close to 40 psi, but not go higher than 45 psi, from your experience is that accurate ?

Thank you by advance.

Hello, thank you for the kind words. Garrett does state 40-45 psi max but this is the oil pressures meant for the ball bearing turbochargers. If these kinds of turbos get too much oil in the bearings they won't spool up as fast or are unable to get to their designed rpm.

For the journal bearing turbochargers like the GT0632SZ turbo, Garrett recommends a hose ID of 0.25" or around 6mm for sufficient oil flow that's all.

However if you do manage to push too much oil to the turbo like 100 psi or have a blocked oil return, the only thing that can happen is worst case you blow the oil seals. But more likely before that you would notice the oil seeping through the seals causing blue smoke if you have the turbo running. If that happens reducing the oil pressure a bit more should stop the leaks.

Hello their . I have a suzuki gs 400 and a suzuki gs 250 im planning to turbo the 400cc twin cylinder 4stroke . The gt 6 is going to be the best setup for this or im going to the next size ? Id like it to spool and give power from low-medium revs and not push up just in the high revs

Hello George, yes the GT06 turbo would be perfect for the Suzuki gs400 engine. With the GT06 turbo you could take full advantage of the exhaust pulses having twin exhaust runners.

Post a Comment